Onsite Robot Calibration

Calibrate canisters for a range of Dispensing Robots

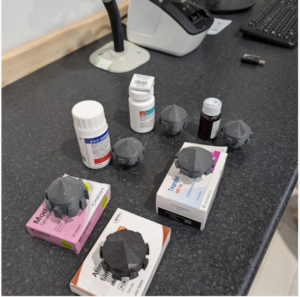

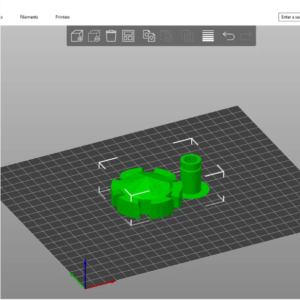

Our innovative solution enables pharmacies to re-calibrate canisters for a variety of popular dispensing robots directly on-site. No need to send anything away—simply use the software to configure and design a new canister. Within 90 minutes, you’ll have the necessary parts and be ready to resume production seamlessly.

Why you should calibrate canisters onsite

Lower Costs

Drug costs are your biggest expense, so having the flexibility to purchase lower-cost or short-line drugs without affecting productivity can significantly reduce your overall costs.

Direct control

No need to send anything away or wait for other companies to respond. With an on-site 3D printer, you can quickly and efficiently produce new canister parts, keeping your operations running smoothly.

Faster Productivity

Properly calibrated canisters ensure smooth production with fewer interruptions. Avoid the frustration of jams caused by trying to fit incompatible brands—precision calibration keeps everything running seamlessly.

Safer dispensing

Poorly fitting canisters can lead to incorrect medication quantities, increasing the risk of “near misses” in your dispensing process. Properly calibrated canisters minimize these risks, protecting both your patients and your business.

One success story

Take inspiration from Bradford Delivery Chemists. Skilled with the Omnicell VBM dispensing robot, their productivity was hindered by frequent brand changes. Zahid Kadri began experimenting with designing his own canisters and was thrilled to discover our solution, which transformed their workflow efficiency.

Calibration Service

As an alternative to having a 3D printer on-site, we offer a calibration service. Simply order canister recalibrations in batches of 5 or 10, and our bank of 3D printers will handle the rest. With a standard turnaround of just 7 days, this provides a cost-effective and efficient solution for your recalibration needs.